honeywell 5000 programming manual

The Honeywell 5000 Programming Manual provides a comprehensive guide for installing, configuring, and operating the FocusPRO 5000 Series thermostat, ensuring optimal performance and energy efficiency for users.

1.1 Overview of the Honeywell 5000 Series Thermostat

The Honeywell 5000 Series Thermostat, part of the FocusPRO lineup, is a non-programmable digital thermostat designed for reliability and ease of use. It offers straightforward installation and operation, making it suitable for various heating and cooling systems. The thermostat features a user-friendly interface with basic functionality, allowing manual temperature adjustments and maintaining settings until the next programmed change. Its design ensures compatibility with conventional and heat pump systems, providing flexible installation options. With clear guidelines outlined in its manual, the Honeywell 5000 Series is ideal for homeowners seeking efficient climate control without advanced programming complexity. The thermostat also supports troubleshooting and maintenance tips, ensuring optimal performance and energy efficiency.

1.2 Importance of Programming for Optimal Performance

Programming the Honeywell 5000 Series thermostat is essential for maximizing its efficiency and performance, even though it is a non-programmable model. By setting specific temperature schedules, users can ensure consistent comfort while minimizing energy consumption. The thermostat allows manual overrides, enabling temporary adjustments that persist until the next programmed change. Proper configuration ensures compatibility with various heating and cooling systems, including conventional and heat pump setups. Programming also helps in maintaining optimal operation, reducing the risk of errors, and extending the lifespan of the device. By following the guidelines in the manual, users can tailor the thermostat’s settings to their lifestyle, achieving a balance between energy savings and comfort. This ensures the Honeywell 5000 Series operates at its full potential, delivering reliable performance for years to come.

Installation and Setup

The Honeywell 5000 Series installation involves wallplate mounting, wiring conventional or heat pump systems, and thermostat setup, ensuring proper configuration for reliable operation and energy efficiency.

2.1 Wallplate Installation Process

The wallplate installation for the Honeywell 5000 Series thermostat begins with removing the existing thermostat and preparing the wall. Align the wallplate with the mounting holes, ensuring it is level and secure. Use the provided screws to fasten it firmly. For systems with no existing wallplate, drill pilot holes to avoid damaging the wall. Carefully manage the wires, connecting them to the appropriate terminals as per the manual. Once the wallplate is installed, proceed to mount the thermostat. Proper alignment and leveling are crucial for accurate temperature sensing and smooth operation. Follow the manufacturer’s guidelines to ensure a secure and correct installation. This step is essential for the thermostat’s functionality and energy efficiency.

2.2 Power Options and Wiring Requirements

The Honeywell 5000 Series thermostat supports various power options, including 24V AC and battery power, ensuring flexibility for different HVAC systems. Wiring requirements vary based on the system type, such as conventional, heat pump, or dual-fuel configurations. For conventional systems, connect the R, W, Y, and G terminals accordingly. Heat pump systems may require additional wiring for the reversing valve (O/B terminal). Ensure all connections are secure and match the terminals specified in the manual. Proper wiring is critical for safe and efficient operation. Always refer to the wiring diagram in the manual to avoid errors. If unsure, consult a licensed electrician or the customer support team for assistance. Correct wiring ensures optimal performance and prevents potential damage to the thermostat or HVAC system.

2.3 Mounting the Thermostat

Mounting the Honeywell 5000 Series thermostat requires careful preparation to ensure proper installation and functionality. Begin by turning off the power to your HVAC system at the circuit breaker. Remove the existing thermostat and detach the wires, taking note of their connections. Install the wallplate provided with the Honeywell 5000, ensuring it is level and securely fastened to the wall. Align the thermostat with the wallplate and gently press it into place until it clicks. Connect the wires to the appropriate terminals, matching the wiring diagram in the manual. Ensure the thermostat is placed in a location with consistent temperature, avoiding direct sunlight or drafts. Secure the thermostat firmly to the wallplate to prevent any movement. Proper mounting ensures accurate temperature sensing and reliable operation. Double-check all connections before restoring power to the system. If unsure, consult the installation guide or contact customer support for assistance. This step is crucial for optimal performance and safety. Proper installation ensures longevity and efficiency of the thermostat. Always follow the manufacturer’s guidelines for mounting to avoid damage or malfunction. Mounting the thermostat correctly is essential for maintaining consistent heating and cooling in your home or office. Ensure the thermostat is accessible for future adjustments and programming. Proper alignment and secure fastening are key to preventing any operational issues. By following these steps, you can ensure your Honeywell 5000 thermostat is mounted correctly and functions as intended. This will help maintain your desired comfort levels while optimizing energy efficiency. Mounting the thermostat is a critical step in the installation process, so take your time to ensure it is done right. If you are unsure about any part of the process, consider consulting a professional to avoid potential issues. Proper mounting is the foundation for reliable thermostat performance, so attention to detail is important. Follow the instructions carefully to complete this step successfully. The Honeywell 5000 thermostat is designed for easy installation, but proper mounting is essential for its functionality. Take care to ensure the thermostat is level and securely attached to the wall. This will prevent any issues with temperature accuracy or wiring connections. Mounting the thermostat correctly also ensures that it blends seamlessly with your home decor, maintaining a clean and professional appearance. By carefully following the mounting instructions, you can enjoy the full benefits of your Honeywell 5000 thermostat. Proper installation and mounting are the first steps toward optimal performance and energy savings. Ensure the thermostat is mounted in a location that provides accurate temperature readings for your space. Avoid placing it near vents, radiators, or other heat sources, as this can affect its performance. Mounting the thermostat in the correct location ensures that it can effectively regulate your HVAC system for consistent comfort. Always refer to the manual for specific guidelines on placement and mounting to achieve the best results. Mounting the Honeywell 5000 thermostat is a straightforward process when following the provided instructions. Take your time to ensure it is done correctly for reliable operation. Proper mounting is essential for the thermostat to function as intended, providing accurate temperature control and energy efficiency. If you encounter any difficulties, do not hesitate to seek assistance from a licensed professional. Mounting the thermostat is a critical step in the installation process, and doing it right ensures years of reliable service. Ensure the thermostat is securely fastened to the wallplate to prevent any movement or misalignment. This step is crucial for maintaining accurate temperature control and overall system performance. Proper mounting also ensures that the thermostat’s display remains clear and accessible for future adjustments. By following the mounting instructions carefully, you can enjoy the full range of features and benefits offered by the Honeywell 5000 Series thermostat. Mounting the thermostat correctly is the final step in the installation process, ensuring that your HVAC system operates efficiently and effectively. Always double-check your work to ensure the thermostat is properly mounted and all connections are secure. This will help prevent any issues and ensure optimal performance. Mounting the Honeywell 5000 thermostat is a simple yet important task that requires attention to detail. By following the instructions, you can ensure your thermostat is installed correctly and functions as intended. Proper mounting is essential for the thermostat to provide accurate temperature control and reliable operation. If you are unsure about any aspect of the process, consult the manual or contact customer support for guidance. Mounting the thermostat is a critical step in the installation process, and proper execution ensures the Honeywell 5000 Series thermostat performs optimally. Take the time to ensure the thermostat is level, securely fastened, and correctly connected to the wiring. This will ensure accurate temperature readings and reliable operation. Proper mounting also ensures that the thermostat remains stable and secure, preventing any potential issues with functionality. By carefully following the mounting instructions, you can enjoy the full benefits of your Honeywell 5000 thermostat, including improved comfort and energy efficiency. Mounting the thermostat is the final step in bringing your HVAC system up to date with the latest technology. Ensure it is done correctly to maximize performance and longevity. Proper mounting is essential for the Honeywell 5000 thermostat to function as intended, providing accurate temperature control and energy savings. If you encounter any challenges, do not hesitate to seek professional assistance. Mounting the thermostat is a critical step in the installation process, and proper execution ensures reliable operation and optimal performance. Ensure the thermostat is securely attached to the wallplate and all wiring connections are correct. This will help prevent any issues and ensure your Honeywell 5000 thermostat functions as intended. Proper mounting is essential for the thermostat to provide accurate temperature readings and reliable operation. Follow the instructions carefully to ensure a successful installation. Mounting the Honeywell 5000 thermostat is a straightforward process when following the provided guidelines. Take your time to ensure it is done correctly for optimal performance and energy efficiency. Proper mounting ensures the thermostat remains stable and secure, providing accurate temperature control for your HVAC system. If you are unsure about any aspect of the installation, consult the manual or contact customer support for assistance. Mounting the thermostat is a critical step in the installation process, and proper execution ensures the Honeywell 5000 Series thermostat performs optimally. Ensure the thermostat is level, securely fastened, and correctly connected to the wiring. This will help maintain accurate temperature readings and reliable operation. Proper mounting also ensures that the thermostat remains accessible for future adjustments and programming. By carefully following the mounting instructions, you can enjoy the full benefits of your Honeywell 5000 thermostat, including improved comfort and energy efficiency. Mounting the thermostat is the final step in bringing your HVAC system up to date with the latest technology. Ensure it is done correctly to maximize performance and longevity. Proper mounting is essential for the Honeywell 5000 thermostat to function as intended, providing accurate temperature control and energy savings. If you encounter any challenges, do not hesitate to seek professional assistance. Mounting the thermostat is a critical step in the installation process, and proper execution ensures reliable operation and optimal performance. Ensure the thermostat is securely attached to the wallplate and all wiring connections are correct. This will help prevent any issues and ensure your Honeywell 5000 thermostat functions as intended. Proper mounting is essential for the thermostat to provide accurate temperature readings and reliable operation. Follow the instructions carefully to ensure a successful installation. Mounting the Honeywell 5000 thermostat is a straightforward process when following the provided guidelines. Take your time to ensure it is done correctly for optimal performance and energy efficiency. Proper mounting ensures the thermostat remains stable and secure, providing accurate temperature control for your HVAC system. If you are unsure about any aspect of the installation, consult the manual or contact customer support for assistance. Mounting the thermostat is a critical step in the installation process, and proper execution ensures the Honeywell 5000 Series thermostat performs optimally. Ensure the thermostat is level, securely fastened, and correctly connected to the wiring. This will help maintain accurate temperature readings and reliable operation. Proper mounting also ensures that the thermostat remains accessible for future adjustments and programming. By carefully following the mounting instructions, you can enjoy the full benefits of your Honeywell 500

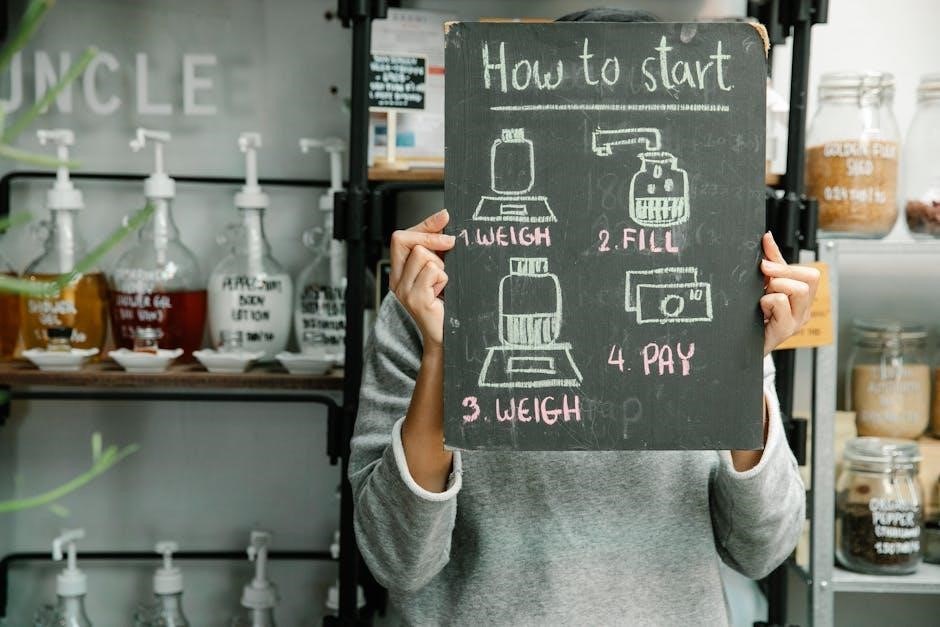

Programming the Thermostat

Programming the Honeywell 5000 thermostat involves setting schedules, temperature preferences, and advanced features like energy-saving modes and security codes to optimize performance and energy efficiency.

3;1 Basic Programming Steps

Basic programming steps for the Honeywell 5000 thermostat involve setting the time, temperature, and scheduling preferences. Start by entering the current date and time using the thermostat’s interface. Next, set your desired temperature levels for heating and cooling modes. Define schedules by creating time-based temperature adjustments, ensuring energy efficiency. Use the temperature buttons to adjust settings and save changes. Enable features like manual override to temporarily bypass programmed settings. Advanced options include energy-saving modes and security codes to enhance functionality. By following these steps, users can customize their thermostat to meet specific comfort and energy-saving needs. Proper programming ensures optimal performance and seamless operation of the Honeywell 5000 thermostat.

3.2 Scheduling Options

The Honeywell 5000 thermostat offers flexible scheduling options to optimize comfort and energy usage. Users can create daily and weekly schedules, setting specific temperatures for different times of the day. The thermostat allows for multiple periods within a day, enabling precise control over heating and cooling. For example, users can set a lower temperature during sleep hours or when the house is unoccupied. Schedules can be customized to align with personal routines, ensuring the system operates efficiently. The thermostat also supports holiday programming, allowing users to override schedules temporarily. These scheduling features help maintain consistent comfort while reducing energy consumption. By tailoring temperature settings to daily activities, users can achieve significant energy savings without compromising on comfort. The intuitive interface makes it easy to create and adjust schedules to suit any lifestyle or preference.

3.3 Advanced Programming Features

The Honeywell 5000 thermostat offers advanced programming features to enhance energy efficiency and user convenience. These include programmable fan control, which allows users to customize fan operation for consistent air circulation. Additionally, the thermostat supports geofencing, enabling location-based temperature adjustments for improved energy savings. Advanced features also include smart recovery, which learns the system’s performance to reach desired temperatures at scheduled times. Users can also set up energy-saving modes and customize temperature ranges to prevent excessive heating or cooling. These features provide granular control over the system, ensuring optimal performance and energy efficiency. By leveraging these advanced options, users can tailor the thermostat’s behavior to their specific needs, achieving both comfort and cost savings. These capabilities make the Honeywell 5000 a versatile and intelligent solution for modern heating and cooling systems.

Operating the Thermostat

Learn to manually override programmed settings, adjust temperatures, and understand the display for seamless control. This section covers daily operations to maintain comfort and efficiency effortlessly.

4.1 Manual Override of Programmed Settings

To manually override programmed settings on the Honeywell 5000 thermostat, use the temperature adjustment buttons. This feature allows temporary changes without altering the scheduled program. The thermostat will revert to the programmed settings at the next scheduled time. Manual overrides are ideal for unexpected temperature preferences. Ensure the thermostat is in the correct mode (Heat or Cool) before making adjustments. The display will show the temporary setpoint until the next scheduled change. This function provides flexibility while maintaining energy-saving programmed schedules. Always refer to the manual for detailed step-by-step instructions to ensure proper operation and optimal performance.

4.2 Understanding the Thermostat Display

The Honeywell 5000 thermostat features a user-friendly display that provides clear information about current settings and system status. The screen shows the current temperature, setpoint, and mode (Heat/Cool) in large, easy-to-read digits. Additional indicators, such as a flame icon for heating or snowflake for cooling, help users quickly understand the active mode. The display also shows the time and day, ensuring schedules are followed accurately. Status messages and error codes appear if issues arise, guiding users to resolve problems efficiently. The backlight ensures visibility in low-light conditions. Understanding the display is essential for monitoring and adjusting settings effectively, ensuring optimal comfort and energy efficiency. Always refer to the manual for detailed explanations of all display elements and their functions.

Troubleshooting Common Issues

The Honeywell 5000 thermostat display shows error codes and status messages to help identify and resolve issues quickly, ensuring optimal performance and user convenience always.

5.1 Identifying and Resolving Common Errors

The Honeywell 5000 thermostat may display error codes such as “E1” or “E2,” indicating issues like sensor malfunctions or communication problems. Users should first check wiring connections and ensure proper installation. If the display shows a “LO” or “HI” error, it may signify temperature extremes or faulty sensors. Resetting the thermostat by removing batteries or power cycling can often resolve these issues. For persistent errors, consulting the user manual or contacting customer support is recommended. Regular maintenance, such as cleaning sensors and updating firmware, helps prevent errors. Understanding these troubleshooting steps ensures optimal performance and extends the thermostat’s lifespan.

5.2 Error Codes and Their Solutions

The Honeywell 5000 thermostat displays error codes to indicate specific issues. Common codes include “E1” for sensor malfunctions and “E2” for communication errors. “LO” or “HI” errors suggest temperature extremes or faulty sensors. To resolve these, check wiring connections, ensure proper installation, and reset the thermostat by removing batteries or power cycling. If issues persist, refer to the user manual for detailed troubleshooting steps or contact Honeywell support. Regular maintenance, such as cleaning sensors and updating firmware, can prevent errors. Understanding and addressing these codes ensures optimal performance and extends the thermostat’s lifespan. Always follow the manufacturer’s guidelines for resolving errors to avoid further complications.

Maintenance and Upkeep

Regular maintenance ensures the Honeywell 5000 thermostat operates efficiently. Clean the display and sensors, check wiring, and update firmware to maintain optimal performance and functionality.

6.1 Regular Maintenance Tips

Regular maintenance is essential to ensure the Honeywell 5000 thermostat operates efficiently. Start by cleaning the display and sensors to prevent dust buildup, which can affect accuracy. Inspect the wiring for any signs of damage or wear, and ensure all connections are secure. Replace batteries promptly when the low-battery indicator appears to avoid interruptions. Additionally, update the thermostat’s firmware regularly to access the latest features and improvements. Check the date and time settings periodically to ensure scheduling accuracy. Finally, calibrate the temperature sensor if necessary to maintain precise temperature control. By following these maintenance tips, you can extend the lifespan of your thermostat and ensure reliable performance.

6.2 Updating Software and Firmware

Updating the software and firmware of your Honeywell 5000 thermostat is crucial for ensuring optimal performance and accessing new features. Begin by checking if an update is available through the thermostat’s menu or by visiting Honeywell’s official website. Enter the engineer code to access advanced settings, then navigate to the update section. Follow on-screen instructions to download and install the latest firmware. Ensure the thermostat remains powered during the update process to avoid system corruption. Once complete, restart the device to apply changes. Regular updates enhance functionality, improve compatibility with smart home systems, and resolve any software issues. Always refer to the manual for specific guidance on updating your Honeywell 5000 thermostat.

User Assistance and Support

Honeywell offers comprehensive customer assistance, including detailed manuals, online guides, and 24/7 technical support to address any questions or issues with the Honeywell 5000 thermostat.

7.1 Customer Assistance Options

Honeywell provides extensive customer support for the 5000 Series thermostat, including downloadable manuals, online troubleshooting guides, and access to technical support specialists. Users can contact Honeywell via phone, email, or live chat for personalized assistance. The company also offers FAQs and video tutorials to help resolve common issues. Additionally, registered users can access exclusive resources through Honeywell’s official website, ensuring seamless support for programming, installation, and maintenance. This comprehensive assistance ensures users can maximize the functionality of their Honeywell 5000 thermostat with ease and confidence.

7.2 Accessing Technical Support

For technical support with the Honeywell 5000 Series thermostat, users can visit Honeywell’s official website to access detailed resources, including manuals and troubleshooting guides. Additionally, Honeywell offers direct support through toll-free phone numbers, email, and live chat services. Registered users can also log into their accounts for personalized assistance. The company provides 24/7 technical support to address installation, programming, and operational issues promptly. Furthermore, regional offices and authorized service centers are available to offer localized support, ensuring users receive assistance tailored to their specific needs. Honeywell’s commitment to customer satisfaction is evident through its robust support network, designed to resolve issues efficiently and enhance user experience.

Integration with Smart Home Systems

The Honeywell 5000 Series thermostat seamlessly integrates with popular smart home platforms, enabling voice control and remote scheduling through devices like Amazon Alexa and Google Home systems.

8.1 Compatibility with Smart Home Devices

The Honeywell 5000 Series thermostat is designed to integrate seamlessly with various smart home systems, enhancing convenience and energy management. It is compatible with Amazon Alexa and Google Home, allowing users to control temperature settings via voice commands or mobile apps. Additionally, it works with other smart devices, such as smart hubs and sensors, to create a unified home automation experience. This compatibility enables features like remote access, scheduling, and energy usage monitoring. Users can also integrate the thermostat with security systems for advanced home control. The thermostat’s adaptability ensures it can be part of a broader smart home ecosystem, providing a modern and efficient way to manage indoor comfort and energy consumption.

8.2 Setting Up Smart Home Integration

Setting up smart home integration for the Honeywell 5000 thermostat involves connecting it to a compatible smart home hub or bridge. Ensure your thermostat is connected to your home Wi-Fi network for seamless integration. Use the Honeywell Home app to link the thermostat to your smart home system. Enable voice control by integrating with Amazon Alexa or Google Home through their respective apps. Create custom scenes or routines to automate temperature adjustments based on your schedule or other smart device activities. Secure your setup by updating firmware regularly and using strong passwords. For troubleshooting, refer to Honeywell’s support resources or online forums. This setup enhances convenience and energy efficiency, allowing you to control your home environment effortlessly.

Advanced Features

The Honeywell 5000 thermostat offers advanced features like security protocols, energy management settings, and smart home compatibility, enhancing efficiency and control for optimal performance and comfort.

9.1 Security Features

The Honeywell 5000 thermostat incorporates advanced security features to protect user settings and ensure system integrity. These include the ability to set a master code and user-specific codes, providing controlled access to programming and adjustments. The system also offers a lockout feature, which prevents unauthorized changes to settings, enhancing security in shared environments. Additionally, the thermostat supports relay output configurations, allowing users to integrate with security systems or alarms for added protection. These features ensure that the thermostat’s settings remain secure and tamper-proof, while still allowing authorized users to make necessary adjustments; By implementing these security measures, the Honeywell 5000 thermostat provides a reliable and protected environment for home or commercial use.

9.2 Energy Management Settings

The Honeywell 5000 thermostat offers robust energy management settings to optimize energy consumption and reduce costs. Users can program schedules to adjust temperature settings during peak and off-peak hours, ensuring energy usage aligns with demand. The thermostat also features smart recovery, which pre-cools or pre-heats the space to reach the desired temperature just in time for the next scheduled period. Additionally, the system allows for setting temperature limits, preventing extreme heating or cooling that wastes energy. These features, combined with compatibility with smart home systems, enable users to monitor and control energy usage remotely, promoting efficient and sustainable heating and cooling practices. By leveraging these energy management settings, users can significantly lower their energy bills while maintaining comfort.

The Honeywell 5000 Programming Manual serves as an essential resource for users seeking to maximize the functionality of their thermostat. By following the detailed installation, programming, and troubleshooting guidelines, users can ensure optimal performance and energy efficiency. The manual emphasizes the importance of proper setup and scheduling to achieve comfort and cost savings. With advanced features like energy management settings and smart home integration, the Honeywell 5000 offers a tailored solution for modern heating and cooling needs. By leveraging these tools, users can create a personalized and efficient climate control system. This guide empowers users to take full advantage of their thermostat’s capabilities, ensuring long-term satisfaction and energy savings.